MACHBASE MOS

(Manufacturing Optimization System)

Enables real-time quality management

in complex manufacturing

About Product

Manufacturing

Optimization Suite

Machbase MOS (Manufacturing

Optimization Suite) is the best solution

for real-time process monitoring and

identification of facility and quality

abnormalities through synchronization

of facility status data and product

quality information data.

Linked to production products

quality maintenance monitoring

Through MOS,

companies can build

realistic big data for quality maintenance

monitoring, quality problem tracking,

analyzing causes and utilizing them

by linking sensor data of facilities

and product data.

Corporate profits

and brand value

This will enable companies to reduce

defect rates, improve quality, increase

productivity, trace product production

history, reduce customer claims,

and reduce costs, which will

ultimately increase profits

and value.

Data Collection and Integration

Collect sensor data from various facilities into TSDB

in seconds Collect data linked to customer's

production-related legacy system and ERP/MES into RDBMS

Product Info Data

(to RDBMS)

Sensor Data

(to TSDB)

-

OPC-UA/DA

-

MQTT Pub/Sub

-

Modbus RTU/TCP

-

Melsec

-

Simatic

-

Ethernet

-

Portal

-

ERP

-

MES/POP

-

QMS

-

Legacy

Database Configuration

TSDB

Machbase's time series database,

globally recognized for #1

performance by TPC, efficiently

handles collection, storage, and

processing of sensor

data at high speeds.

RDBMS

Configuring RDBMS to manage

product, facility, and work instruction

information in production processes,

compatible with legacy systems and

adaptable to company needs

AAS

(Asset Administration Shell)

Based on AAS

(Asset Administration Shell),

an industry 4.0 standard, it defines

attributes like production, quality, and

facilities by facility/tag item for

seamless data connection across

departments. It establishes

a foundation to incorporate

standardized AAS information into

production, quality,

and facility processese.

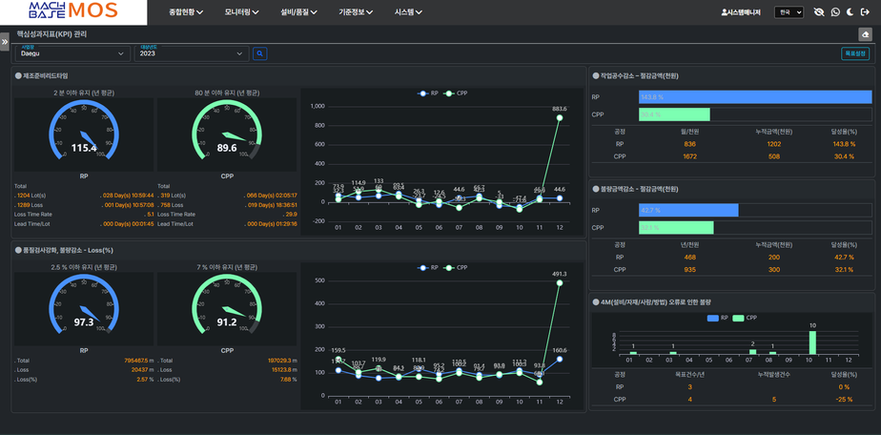

Dashboard and Key Features

Machbase MOS offers real-time data collection, storage, processing,

analysis, and visualization. It includes periodic report generation and

enables comprehensive abnormality detection in facilities, lot-based production performance tracking, and real-time process

monitoring for predictive quality control

MOS UI

* Click to enlarge *